In depth Guide to Valve Manufacturers: Selecting typically the Best Valve Alternatives for Your Industry

Comprehensive Explained Valve Manufacturers: Choosing the right Valve Remedies for Your Industry

Valves are everywhere inside modern industry. They will control the movement of liquids, gas, and even slurries in pipes. Whether in oil rigs, water plants, substance factories, or force stations, valves maintain everything moving as well as efficiently. Because they are so important, picking out the right device manufacturer is a big decision. The trusted manufacturer will give you reliable, long-lasting, and safety-compliant products. As technological innovation advances and criteria change, choosing typically the right partner gets even more essential. In this guide, you'll learn everything an individual need to recognize about valve producing and how in order to find a very good manufacturer regarding your needs.

Understanding Valve Manufacturing: An Industry Overview

The Position of Valves within Industrial Processes

Regulators act like gatekeepers of pipelines. They control when in addition to how fluids move through systems. Plenty of valves start or even stop flow completely, while others manage pressure or heat. For example, inside of coal and oil extraction, regulators help manage high-pressure streams. In water treatment, they help control clean in addition to wastewater flows. This control is critical for safety, efficiency, in addition to environmental protection.

Market Size and Industry Growth

A global regulators market is booming. It was highly valued at over $70 billion in 2022 and it is expected in order to grow annually. This particular growth arises from increased demand in strength, manufacturing, and drinking water infrastructure. Automation is pushing the industry in the direction of smarter valves that can communicate and even adapt. Eco-friendly and even sustainable practices will also be shaping new product or service designs. As industrial sectors push for healthier solutions, valve manufacturers must innovate continually.

Forms of Valves Manufactured

Different applications must different valves. Here are the most common sorts:

Ball valves: Acknowledged for quick shut-off and reliable securing, often used inside of gas and oil.

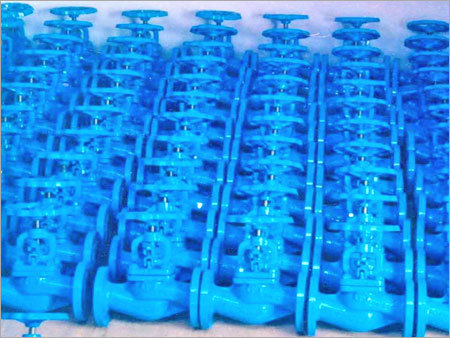

Gate valves: Perfect for full circulation when open, good for on/off services.

Globe valves: Fantastic for regulating movement and pressure.

Butterfly valves: Quick to work and space-efficient, useful in water and wastewater.

Check valves: Avoid backflow, protecting tools.

Control valves: Allow precise control associated with flow rate in addition to process conditions.

Every single type has the strengths, making the particular range of manufacturer crucial for matching your current specific needs.

Essential Factors to Consider When Choosing the Valve Manufacturer

Top quality Standards and Accreditations

Safety and reliability rest on rigid standards. Look intended for manufacturers with certifications like ISO 9001 for quality administration. API standards will be vital for oil and gas projects, while ASME programs ensure mechanical sincerity. These certifications guarantee products are made to good quality, lessening risks of disappointment.

Manufacturing Capabilities and Technologies

Advanced equipment like CNC equipment allow for high-precision valve parts. Robotisation in production likewise cuts costs and speeds up shipping and delivery. In-house research and development mean producers can customize regulators for your special needs, whether that’s handling extreme demands or corrosive chemicals.